Re

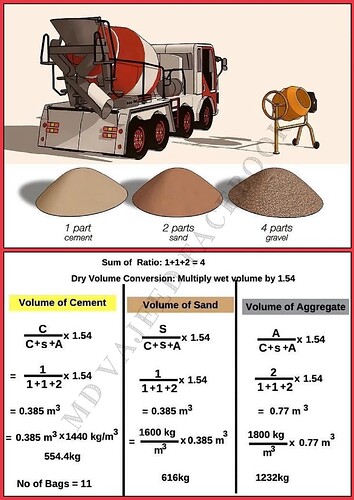

Concrete is the skeleton for most renovation projects. From repairing the bridges to laying the new floors in factory or homes, it offers the strength and stability that every structure requires. Concrete mixers make it possible to combine the ingredients-cement, sand, gravel, and water-into a smooth, consistent mix.

Without the use of mixers, workers would spend hours hand-mixing, and risk uneven results. A poorly mixed batch can crack or weaken over time but a properly mixed load will ensure durability that lasts decades. In the case of road and bridge renovation, such a difference can translate into safer highways and stronger foundations.

Modern mixers have a wide range of sizes. Small versions that were designed to move around on their own are ideal for home renovations, such as patios or driveways, while larger models that are mounted on trucks are used for industrial and infrastructure projects. Their rotating drums keep the mix in constant motion so that it doesn’t harden before it is used.

Efficiency is also another advantage. With the right machine, large quantities of concrete can be mixed fast, minimising delays at the job site. Many of today’s mixers also have energy-efficient motors, which makes them both practical and environmentally responsible.

Conclusion

Concrete mixers are tools of creation They convert basic materials into the building blocks of strength and stability. In the case of renovation, they take care that new layers laid on old foundations are solid, reliable and safe. Every spin of a mixer’s drum is a step closer to renewal - creating the foundation for spaces that will stand tall for years to come.